rockwell hardness test free cutting brass|rockwell c hardness scale chart : import Free Machining brass is the most commonly used of the brass rod and bar items. The presence of lead in the alloy creates a highly machinable material that can easily be cut and . WEB16 de fev. de 2024 · A Pixbet é uma casa com DNA 100% brasileiro, afinal, ela foi criada por empresários do nosso país.. Por isso, entrega tudo o que o apostador daqui mais gosta, como foco em futebol, odds competitivas e depósitos e saques instantâneos.. Segura, a casa conta com mais de 1.000 competições de futebol e inúmeras outras modalidades, .

{plog:ftitle_list}

WEBRoblox is the ultimate virtual universe that lets you create, share experiences with friends, and be anything you can imagine. Join millions of people and discover an infinite variety of immersive experiences created by a global community!

custom moisture meter review 2015

Free-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 mm rod. Categories: Metal; Nonferrous Metal; Copper Alloy; Brass. Material Notes: Fair to excellent corrosion .C36000 (Free-Cutting Brass) Chemical Composition (%max., unless shown as range or min.) Cu Fe Pb Zn Min./Max.60.0-63.0.352.5-3.0Rem. Nominal 61.5 - 2.7 35.4 . Rockwell Hardness .

This specification establishes the requirements for free-cutting brass rod, bar, wire, and shapes of any specified cross-section produced from Copper Alloy UNS No. C36000 .Free Machining brass is the most commonly used of the brass rod and bar items. The presence of lead in the alloy creates a highly machinable material that can easily be cut and .Free-Cutting Brass, UNS C36000, H02 (Cold Drawn 25%) Temper 6 mm rod Categories: Metal; Nonferrous Metal; Copper Alloy; Brass. Material Notes: Fair to excellent corrosion resistance. .Rockwell Hardness: B78; Elongation at Break Percentage: 53%; Poisson’s Ratio: 0.31; Machinability Percentage: 100%; Other Common Names for 360 Brass. In addition to 360 .

custom moisture meter reviews 2017

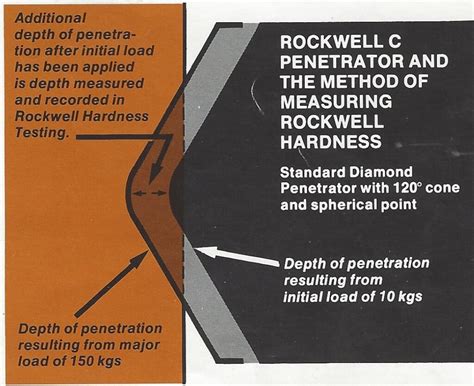

In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the .results. Foremost to any Rockwell test process is identification of the proper hardness scale to be used on the component to be tested. There are 30 different Rockwell scales with the . The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .Brinell hardness of cartridge brass – UNS C26000 is approximately 100 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the .

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds. . Rockwell B scale (RHB): This scale is used for testing harder materials, such as brass, mild .

1. AIM: To determine the Rockwell Hardness of a given test specimen II. APPARATUS: Rockwell Hardness testing machine, Test specimen. III. THEORY: HARDNESS- It is defined as the resistance of a metal to plastic deformation against Indentation, scratching, abrasion of cutting. The hardness of a material by this Rockwell hardness test method is .E18Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials E 478 Test Methods for Chemical Analysis of Copper Alloys 3. General Requirements 3.1 The following sections of Specifications B 249/B 249M (rod, bar, and shapes), and B 250/B 250M (wrought copper alloy wire) constitute a part of this specification.High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the 8.1 Rockwell Hardness: 8.1.1 Product 1Ú2 in. [12 mm], and over in diameter or distance between parallel surfaces, shall conform with the requirements given in Table 4 and Table 5 for temper, size, and form when tested in accordance with Test Methods E18 . 8.1.1.1 Rockwell hardness shall be the acceptance criterion

C36000 (Free-Cutting Brass) Chemical Composition (%max., unless shown as range or min.) Cu Fe Pb Zn Min./Max.60.0-63.0.352.5-3.0Rem. Nominal 61.5 - 2.7 35.4 . Rockwell Hardness Vickens Hard. Brinell Hard. Shear StrengthStrength* Fatigue Izod Impact StrengthIt is a quick and simple measurement, especially suitable for cutlery steels. Vickers hardness test (HV) A pyramidal diamond indenter with a 136° angle is used and the force and surface of the indented pyramid is measured. Mohs scale of mineral hardness The Mohs scale measures hardness of minerals and synthetic materials, characterizing .

Rockwell hardness: Rm: HV: HB: HRC: 250: 80: 76: 270: 85: 80.7: 285: 90: 85.2: 305: 95: . Note: When considering cutting processing, a general conversion of 1HRC ≈ 10HB applies (the hardness of the workpiece material may vary slightly). . Types of Metal Hardness. According to the different test methods, there are three types of hardness .

So, let’s dive into the detailed analysis of brass and beryllium bronze properties, exploring how their hardness and tensile strength characteristics can be leveraged in various engineering applications! Copper Alloy Hardness and Strength Conversion Values (Excerpt from GB/T3771-1983)Hardness of Brass vs Steel and Stainless Steel. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a .Overview of materials for Brass, This property data is a summary of similar materials in the Mat database for the category "Brass". Each property range of values reported is minimum and maximum values of appropriate Mat entries. . Hardness, Rockwell B, Average value: 69.1 Grade Count:274; Hardness, Rockwell F, Average value: 68.9 Grade .Our cut-off machines give you fast, deformation-free cutting in all sizes. All our manual and automated cutting solutions are designed for maximum durability and ease of use. READ MORE. . How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV)

free cutting, FC, CDA 360, CZ124, ISO CuZn36Pb3, CEN CW603N, FED QQ-B-626 (discontinued), ASTM-B121, ASTM-B36, ASTM-B16/B16M, ASTM-B124, Fair to excellent corrosion resistance. Excellent machinability. Fabricated by machining, roll threading andFree-Cutting Brass, UNS C36000, H02 Temper, Bar, Temper: 1/2 Hard Fabrication Properties: Excellent Suitability – Soldering; Good Suitability – Brazing; Fair Suitability – Butt Weld, Capacity for Being Hot Formed, Capacity for Being Cold Worked . Hardness, Rockwell B; Hardness, Rockwell B; Tensile Strength, for Standard; Tensile .free-cutting brass rod, bar and shapes for use in screw machines: rod: sae: j463: wrought copper and copper alloys: ams: 4610: brass bars and rods, free cutting, half-hard: sae: j461: wrought and cast copper alloys: astm: b16/b16m: free-cutting brass rod, bar and shapes for use in screw machines: shapes: sae: j461: wrought and cast copper .

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. . For instance, the HRB scale is employed for testing soft steels, aluminium, and brass, and involves applying minor loads of 10kgf and major loads of 100kgf. On the other hand, the HRC scale is used for .Hardness Conversion for Rockwell C Scale or High Hardness Range . Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing.

Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Here’s a little chart on the minimum material .1. Rockwell hardness test (scales A, B & C) methods : IS:1586-1988 Viva Questions: 1. What is Hardness? 2. What is the significance of minor load in Rockwell method of hardness testing 3. What are the advantages and limitations of Rockwell method of hardness testing 4. Where are Rockwell hardness test and Brinell hard test employed 5. Rockwell Hardness Test . The Rockwell hardness test, developed by Stanley P. Rockwell, is another widely used method for measuring hardness. It involves applying a minor initial load, followed by a major load, and then measuring the depth of penetration. The hardness value is determined based on the difference in penetration depth under the two .

1.3. Rockwell Hardness Test: The Rockwell hardness test also uses a machine to apply a specific load and then measure the depth of the resulting impression. The indenter may either be a steel ball of some specified diameter or a spherical diamond-tipped cone of 120° angle and 0.2 mm tip radius, called brale.Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y

understanding rockwell hardness scale

Rockwell hardness test - Download as a PDF or view online for free. . (1.588 mm) steel sphere Aluminium, brass, and soft steels C HRC 150 kgf 120° diamond spheroconical Harder steels >B100 D HRD 100 kgf 120° diamond spheroconical E HRE 100 kgf 1⁄8-inch-diameter (3.175 mm) steel sphere F HRF 60 kgf 1⁄16-inch-diameter (1.588 mm) steel .Our cut-off machines give you fast, deformation-free cutting in all sizes. All our manual and automated cutting solutions are designed for maximum durability and ease of use. . How to use the Rockwell hardness test for quick hardness testing in the lab or production environment. Vickers Hardness testing (HV) Hardness Test Average 99.7 227.5 Conversion table value 95 220 Table . Hardness values for aluminum. 6061 Aluminum Rockwell B Test Brinell 10/500 Hardness Test Average 53.825 95.6 Conversion table value 54 87 Table . Hardness values for brass. Brass Rockwell B Test Brinell 10/500 Hardness Test Average 71.1 110.5

typical rockwell hardness of materials

rockwell hardness test chart

WEBQuem aí já experimentou comprar o Totolec digital? É rápido, prático e superseguro. Com poucos cliques, você adquire sua cartela da semana e concorre a um show de prêmios que vai dar um UP na sua vida! Acesse app.totolecshow.com.br e compre sua cartela! #TotolecDigital #MudeDeVida

rockwell hardness test free cutting brass|rockwell c hardness scale chart